-

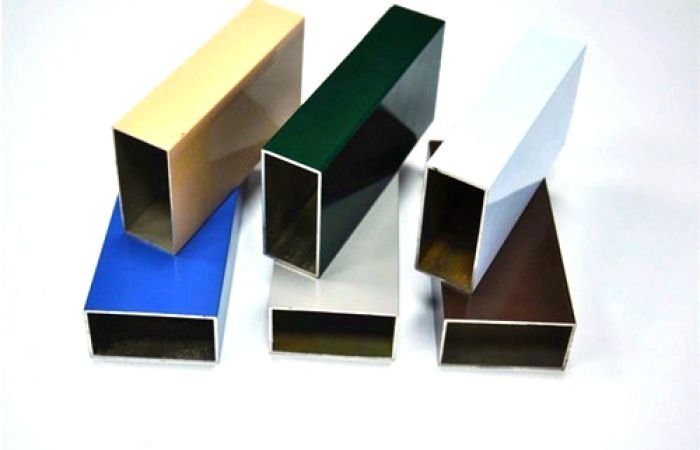

Steel Powder Coating

Powder coating is applied as a dry powder on the steel. Powder coating uses an electrostatic application process followed by a heated curing process in a curing oven. To create adhesion, the pigment and resin are charged with static electricity and then sprayed onto steel that is electrically grounded.

-

MS Powder Coating

Powder Coating is a dry finishing process created by an electric charge that causes a dry powder to fuse to the surface of the metal. This is then baked in a curing oven to achieve a smooth coating. It is usually used to create a hard finish that is tougher than conventional paint.

-

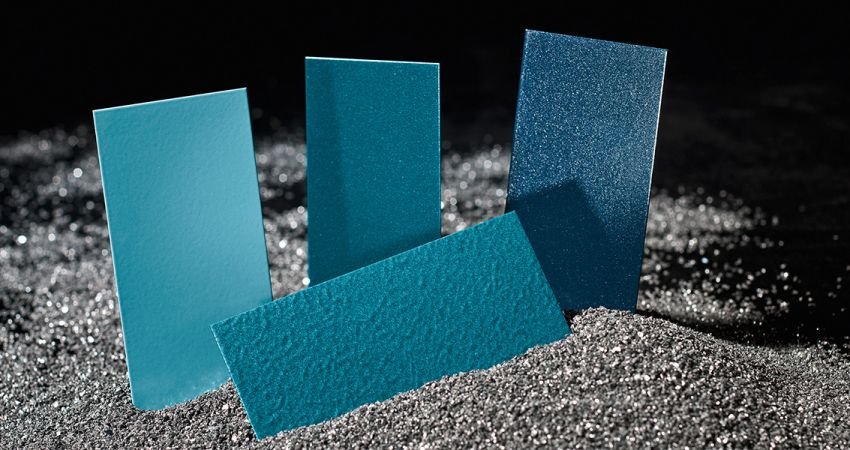

Aluminium powder coating

Powder coating is a type of coating that is applied to aluminium extruded profile surfaces as a dry powder. It is typically used to protect and improve the appearance of metal surfaces, such as automotive parts, architectural elevations .Aluminum powders are used in paints, pigments, protective coatings, printing inks, rocket fuel, explosives, abrasives and ceramics; production of inorganic and organic aluminum chemicals; and as catalysts. Pyro powder is mixed with carbon and used in the manufacture of fireworks.

- Wood Coating

Wood effect powder coating in a nutshell is an additional process to usual powder coating to give it a grain like finish similar to wood. This finish is perfect for people wanting the long lifespan and low maintenance of steel but prefer the more traditional look that wood gives. wood powder are as fuel in the form of sawdust powder and briquettes, as a raw material for perfume production, a core material for japanwares, heat insulating material and also some agricultural uses.